Purpose: Cold Forging (Servo Presses)

Frame :Straight

Capacity :4000〜6300kN

Point :1pt

All the factors that expand possibility of cold forging are in this one :

• Solid loop frame of high rigidity and reliability

• Plunger guide for high precision

• MAY PRESS motion for excellent formability

• Free motion that expand possibility of cold forging

Effects of free motion:

1) Seizure-proof and productivity are increased.

2) Application range can be expanded to complex forming. (enclosed die forging, multidirectional forging, back pressure forging etc.)

Komatsu’s original MAY PRESS link motion makes touching speed to forming area remarkably slow to create a smooth plastic flow and realizes stable high precision forming. In addition, such motions as making speed slower only at certain positions to enhance formability and as making the slide reciprocating to improve fluidity and stretchability are made possible by free motion setting.

With the servo BKO that enables flexible back pressure control, flow of material can be controlled to widen forming ranges.

This is realized with the AC servo of the die cushion.

• Shorter cycle time with highly responsive system

• Shorter preparation time

• Forming highly difficult-to-form products with the most suitable control of thrust force to the plate

• Reducing stage number

• Lower touch noise with impact pressure control like preliminary acceleration and shock-less stop

• Power regeneration

• Easier maintenance

From Kyoto Tool Co., Ltd.

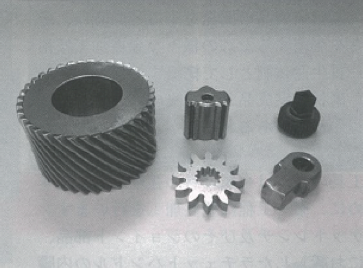

Example of backward extrusion product

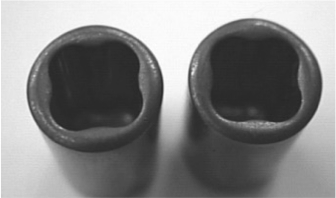

Example of ironing product

Function of the servo press is important for cold sinter forging of 35 degree helical gears. We had to increase density efficiently by minutely adjusting slide motions to minimize lowering of productivity, which was impossible with a mechanical press.