Purpose: Precision,General

Frame :Straight

Capacity :2000〜3000kN

Point :2pt

The combination of Industry’s top class stroke length and high speed pendulum motion provides best motions with high moldability, high productivity and high accuracy for each product.

Die height and load are controlled at a constant level with Komatsu’s own technology by Linear scale and Strain gauge.

It can reduce the frequency of inspection of die height.

It is capable of producing high energy regardless of the production speed.

The work energy does not decrease even if SPM is slowed down for improving formability. Deep-drawn products that could not be formed with conventional mechanical presses can be formed with H2W.

From Matsushita Kinzoku Kougyo

We were interested in the control with dual independent servo motors on the Komatsu’s original two point press. Stroke of previous 150ton press by other maker was 130 mm and had a limit in formable products. The standard stroke of of our new H2W200 (S specification) is 250 mm. And knowing that short stroke forming is possible without reducing SPM utilizing the pendulum motion, we will use it as a more versatile machine.

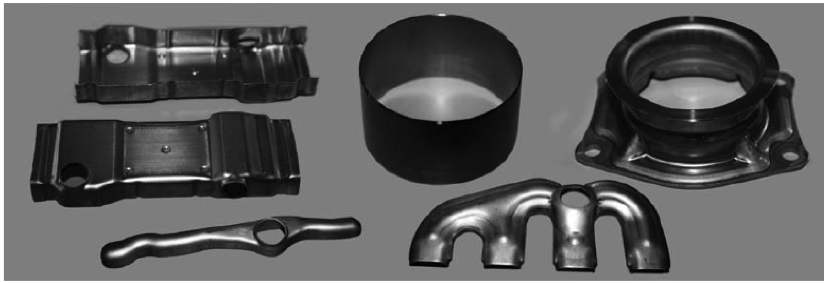

We have greatly reduced number of work stages with “press forming” using a servo press in manufacturing such products as many machine works were required and as were ever produced with forging.

We have been using Komatsu servo presses for five years and have never had a problem of product quality. We are now highly appreciated by clients.